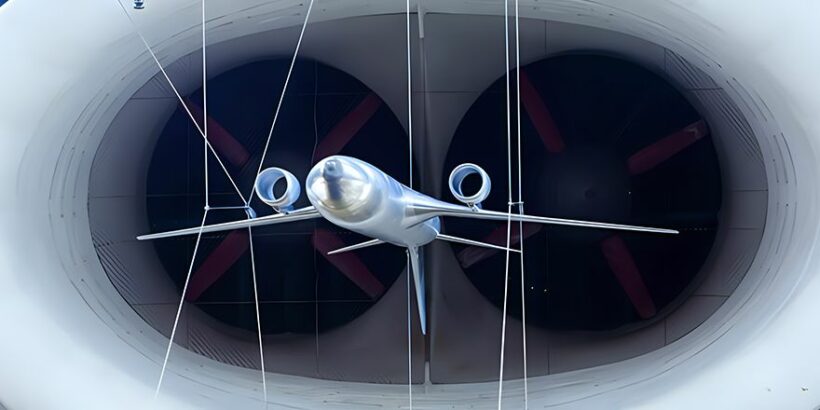

During 2022-2024, research and development programs codenamed “Integral-MS,” “Integral-RS,” and “Integral-T” established the foundation for next-generation mainline and regional aircraft development. Under the “Integral-MS” project, the Central Aerohydrodynamic Institute (TsAGI) developed the mainline aircraft configuration, optimized aerodynamic layout and structural design, manufactured aerodynamic models and mockups, and created an integrated structure demonstrator with corresponding strength testing facilities. The institute conducted bench and laboratory tests, along with wind tunnel evaluations, and prepared technical proposals for creating a comprehensive technology demonstrator featuring an oval fuselage, mid-mounted wing, and integrated wing root extension.

Simultaneously, under the “Integral-RS” project, TsAGI collaborated with the Baranov Central Institute of Aviation Motor Development (CIAM) and the Chaplygin Siberian Research Institute of Aviation (SibNIA) to develop regional aircraft configurations incorporating active flow control (AFC) technologies and distributed electric propulsion systems. Technology demonstrators for AFC were created and experimental studies conducted. Primary objectives included improving takeoff and landing performance, reducing fuel consumption through AFC and distributed propulsion implementation, decreasing harmful emissions, and enhancing flight safety while reducing operational costs through advanced monitoring and diagnostic systems.

The “Integral-T” research program encompassed computational and experimental studies and validation of technologies applicable to both mainline and regional transport category aircraft. Focus areas included enhancing flight performance characteristics, improving aerodynamic and acoustic properties of airframe and landing gear components, and developing intelligent avionics systems to reduce pilot workload and increase safety.

On May 30, 2025, according to government procurement records, a state contract was signed for research and development work to establish the scientific and technical foundation for next-generation mainline and regional aircraft development (codename “Integral”), representing a comprehensive continuation of the aforementioned “Integral-MS,” “Integral-RS,” and “Integral-T” projects.

“The new research program aims to further develop and integrate technologies to support creation of new aircraft with characteristics exceeding previous developments,” states the contract’s technical specification. The Zhukovsky National Research Center serves as contractor, with Russia’s Ministry of Industry and Trade as the customer. The total contract value amounts to 13.435 billion rubles (approximately $145 million USD).

The “Integral” project focuses on acquiring competencies, technologies, and materials for developing aircraft with improved environmental and economic characteristics. Reducing CO₂ emissions, decreasing noise levels, enhancing energy efficiency, and improving flight safety will ensure compliance with current and future ICAO requirements. Fleet modernization will strengthen technological independence and competitiveness of Russian civil aviation.

The project includes creating technology demonstrators and prototypes to validate and refine innovative solutions for serial production launch. Precise technical specifications and demonstrator test results will determine subsequent development phases and production scaling.

Project work is scheduled for completion within three years from the contract signing date of May 30, 2025, with phased annual funding. The financing schedule reflects gradual increases in research volume and intensity, along with technology demonstrator and prototype preparation and testing. For 2025, approximately 550 million rubles ($6 million USD) is allocated for project implementation, with roughly 6 billion rubles ($65 million USD) in 2026 and over 7 billion rubles ($76 million USD) in 2027.

The contract specifies five main phases, including computational and experimental research, hybrid gas turbine engine development, aerodynamic and propulsion system demonstrator creation and testing, and avionics suite development for advanced mainline and regional aircraft. Contract completion is scheduled for December 1, 2027.

The technical concept centers on creating two aircraft types. The first is the “Region-Integral” regional passenger aircraft designed for 36-40 passengers, with cruise speeds up to 435 mph (700 km/h) and range up to 1,553 miles (2,500 km). Its powerplant will be hybrid, incorporating a turboshaft engine—potentially the VK-2500—and distributed electric propulsion based on hydrogen fuel cells.

The VK-2500 selection is based on its proven operational reliability and high specific power output of approximately 2,550 horsepower at takeoff power. The turboshaft engine features simple construction, facilitating maintenance and reducing operational costs. Electric impellers positioned on wing consoles will provide high-lift system flow enhancement and increased lift generation, reduce main engine load, and improve overall energy efficiency.

The second type is the “Magistral-Integral” mainline aircraft accommodating up to 260 passengers, with cruise speeds of 540 mph (870 km/h) and range exceeding 6,214 miles (10,000 km). It is planned to be equipped with future advanced turbofan engines. In 2023, the Zhukovsky Research Center director mentioned using an engine designated PD-24 for the “Magistral-Integral” project; however, United Engine Corporation (UEC) subsidiaries have no development plans for such a powerplant, despite PD-24 (24-ton thrust) being mentioned in Alexander Inozemtsev’s MKD-2022 presentation in the context of a prospective transport aircraft with 80-100 ton payload capacity.

The “Magistral-Integral” project will feature an oval fuselage and mid-mounted integrated wing with root extension, constructed from composite and metal-composite materials with titanium and aluminum alloy elements. Bionic structural applications will also be explored.

TsAGI will perform aerodynamic design and testing of aircraft models and components. The institute’s wind tunnels will conduct tests of the integrated wing with root extension and evaluate electric impeller wing flow interaction. To optimize aircraft configuration and technical parameters, minimize errors, and reduce development timelines, TsAGI will apply multidisciplinary design optimization and systems analysis methods. The institute will also participate in technology demonstrator creation and ensure aerodynamic solution validation on experimental prototypes.

CIAM is responsible for powerplant development and testing. For the “Region-Integral” project, CIAM will create the hybrid propulsion system. For the mainline aircraft, the institute will focus on noise reduction, durability enhancement, and environmental performance improvements.

The All-Russian Scientific Research Institute of Aviation Materials (VIAM) develops new high-strength alloys and composites, along with their production technologies. The projects incorporate composite, metal-composite, and bionic structures to reduce weight and increase strength of fuselage, wing, and other aircraft components. VIAM will develop integrated wing and root extension manufacturing technologies. The institute possesses extensive experience in new material development and testing under conditions approximating real operational environments, also participating in new solution certification.

The Zhukovsky Research Center will coordinate collaborative work among all institutes, ensuring integration of aerodynamic, propulsion, and materials science developments. This approach enables comprehensive technological solutions and reduces risks in transitioning from research to design work and production. Regular joint testing and results sharing will ensure consistent achievement of established objectives.

Andrey Velichko, editor-in-chief of “Aviation of Russia” website, noted that the Ministry of Industry and Trade’s next-generation aircraft development project represents a comprehensive scientific and technical program uniting leading Russian specialized institutes. “It aims to develop domestic aviation industry using modern aerodynamics, propulsion, and materials science technologies. Work results will ensure technological independence of our aviation sector and create prospects for fleet modernization and air transportation efficiency improvements,” he stated.

According to him, implementation of hybrid and electric propulsion systems, new composite and bionic materials, and intelligent control systems directly impacts new aircraft lifecycle performance indicators. Composite material use is expected to reduce structural weight by 10-15%, leading to decreased fuel consumption and operational costs.

“Hybrid propulsion systems provide potential for 15-20% specific fuel consumption reduction compared to traditional counterparts, while transition to hydrogen fuel cells could eventually reduce CO₂ emissions to near zero. However, such solutions may increase aircraft ownership costs in early operational phases and require significant infrastructure investments,” emphasized Andrey Velichko.

He added that successful “Integral” project implementation and ensuring domestic aircraft competitiveness in international markets requires active import substitution development and modern digital technology integration.

Zhukovsky Research Center’s Position in Global Aviation Industry

On a global scale, the Zhukovsky Research Center holds status as one of the largest aerodynamic and aviation scientific centers, comparable in competency level and infrastructure to leading foreign institutes and research divisions of giants like Airbus, Boeing, and COMAC. The center actively develops technological foundations for new aircraft models, emphasizing innovations in aerodynamics, composite materials, control systems, and environmental standards.

However, Russian aviation faces several challenges: limited access to Western markets and intense competition from global leaders. Unlike Airbus and Boeing, which possess extensive international certification networks, Russian projects require enhanced certification work and adaptation to foreign aviation regulatory requirements. China’s COMAC actively promotes its developments in domestic and international markets, intensifying competitive pressure.

| Parameter | Airbus / Boeing | COMAC | Zhukovsky Research Center (Russia) |

|---|---|---|---|

| Market | Global, established | Domestic and export | Domestic, export — future goal |

| Innovations | Composites, digitalization | Localization, new models (but with high share of imported components) | Aerodynamics, hybrid power systems |

| Certification | EASA, FAA | Seeking EASA/FAA approval (challenging due to imported systems) | Adapting to EASA, FAA, ICAO standards |

| Export Strategy | Extensive global network | Active promotion despite dependency on foreign supplies | Under development |

Airbus and Boeing are global leaders with powerful research centers and innovation implementation experience, including composite materials (Boeing 787 Dreamliner) and digitized control systems. Their projects focus on maximum economy, environmental performance, and strict international certification standard compliance (EASA, FAA).

COMAC (China) actively develops proprietary passenger aircraft models like the C919 and C929, declaring reduced dependence on Western manufacturers. However, localization remains limited in practice: key C919 systems and components—engines, avionics, control systems, and other elements—are predominantly manufactured by foreign companies. For example, C919 uses LEAP-1C engines (CFM International, a GE-Safran joint venture), Collins Aerospace avionics, Honeywell control systems, and other Western suppliers. Despite import substitution strategy, COMAC’s actual technological independence remains unachieved, with significant dependence on global supply chains.

Recent years have seen China accelerate development of indigenous aviation technologies and components under geopolitical influences and sanctions pressure, but transitioning to fully independent production requires substantial investment and time. Regarding certification, COMAC seeks international standard recognition (EASA, FAA), critical for foreign market entry, though this process involves additional complexities due to high imported system percentages and the need for foreign regulatory compliance.

The Zhukovsky Research Center develops technological foundations for competitive aircraft creation, adapting domestic technologies to international standards—a necessary condition for foreign market entry and export potential expansion.

Certification, International Standards, and Export Prospects

A key focus of Zhukovsky Research Center work is ensuring new developments comply with international aviation regulatory requirements: FAA (USA), EASA (EU), and ICAO. This includes:

– Developing and implementing technologies meeting safety standards and environmental regulations

– Conducting testing and certification procedures according to international protocols

– Collaborating with foreign partners for experience exchange and global supply chain integration

Successful certification is critical for introducing Russian passenger aircraft to international markets, expanding sales geography, and enhancing domestic aviation technology competitiveness.

Foreign Market Entry Prospects

Despite economic and political barriers, the Zhukovsky Research Center aims to create technological foundations enabling Russian aircraft manufacturers to compete for global market share. Special attention focuses on short- and medium-haul aircraft development, demanded in growing regional transportation markets. Successful foreign market entry requires breakthrough technological solutions providing superiority over existing Airbus, Boeing, and COMAC models. This demands not only technical innovations but comprehensive government support, export-oriented program development, and international cooperation.