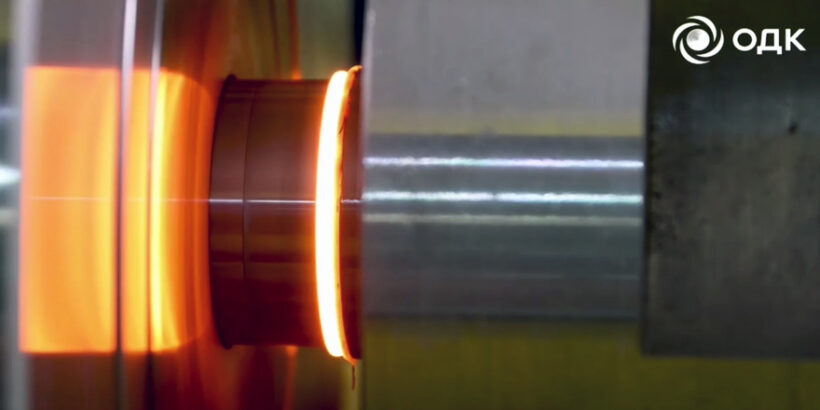

Friction welding (FRW) is a cutting-edge technology for joining dissimilar materials that cannot be joined using conventional fusion welding techniques. The method relies on the heat generated by friction between the surfaces being joined.

“The high temperature required for welding is created by friction between the surfaces under the influence of rotation of one of the parts and simultaneous compressive force. Thanks to this, FRW allows for obtaining joints with improved mechanical properties and minimises defects that typically occur during casting. This technology is becoming increasingly sought after in aero engine manufacturing,” the United Engine Corporation press service told Aviation of Russia website.

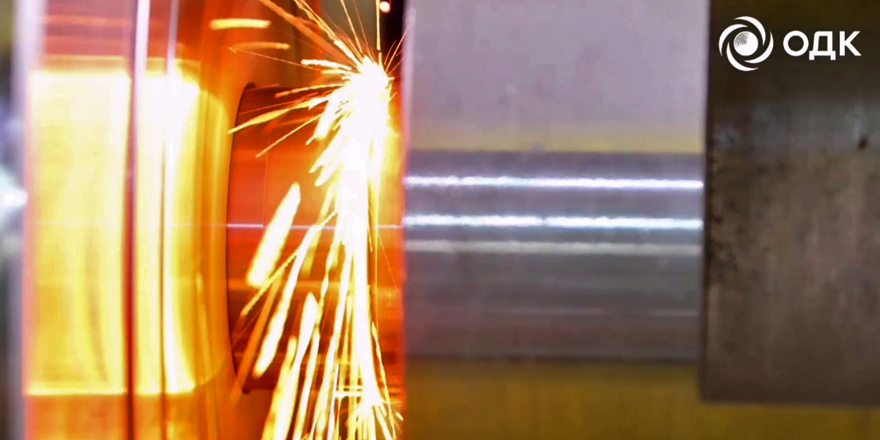

The principle of FRW is simple and elegant. Mechanical energy from friction is converted into thermal energy, sufficient to bring the material in the joint zone into a plastic state. When the required temperature is reached, rotation is stopped, and axial pressure is applied. This process ensures the displacement of contaminants and creates conditions for the diffusion bonding of atoms in the parts being welded. In effect, the materials are “grown together” at a molecular level.

A key advantage of FRW is the ability to join dissimilar materials that are practically impossible to join by traditional methods. For example, steel and aluminium, titanium and copper. A narrow heat-affected zone minimises changes in the material’s microstructure. This is particularly important for high-strength alloys, where any structural changes can lead to a deterioration in properties. Thus, FRW enables the original properties of the materials in the weld zone to be preserved.

There are several types of friction welding. Rotary FRW is the most common method, used for joining cylindrical parts. Friction stir welding (FSW) uses a rotating tool to stir the material and is widely used for aluminium alloys. Linear FRW allows complex-shaped parts to be joined using linear oscillating movements. Rotary and linear friction welding are critically important technologies in modern aero engine manufacturing.

Despite all the advantages, FRW also has limitations. Firstly, specialised equipment is needed. Secondly, there are certain limitations on the shape of the parts being welded. Thirdly, a burr (flash) is formed after welding, which requires additional processing. However, the advantages of FRW often outweigh these disadvantages, particularly where high joint strength and reliability are required.

The use of FRW in the aviation industry is a clear example of its versatility and effectiveness. It is used to manufacture gas turbine engine (GTE) turbine blades, where high joint strength and heat resistance are important. Another promising area is the joining of titanium alloys in fuselage structures.

The introduction of FRW makes it possible to reduce the weight and increase the service life of aero engines without reducing the strength of the welded joints. For example, friction welding technologies are actively used in modern PD-14 engines for the manufacture of turbine discs and other critical parts. This has significantly increased the engine’s reliability, and will subsequently allow the service life of the parts to be brought up to the level of foreign counterparts.

Russian enterprises are actively implementing friction welding, and the prospects for the technology look promising. There is currently active discussion of the possibilities for expanding the area of application of FRW, and specific tasks are being formulated for partners. In particular, this concerns the development of new alloys and welding regimes that will be optimised for specific tasks in the aviation industry. This will make it possible to make the most effective use of the advantages of FRW in the creation of aero engines.

Based on materials from UEC Joint-stock company and publicly available specialized resources, including:

* “Friction Welding and Friction Stir Welding Processes in Aerospace Applications,” Journal of Materials Engineering and Performance

* “Advances in Solid-State Joining Technologies for Aerospace Materials,” SAE International