Specialists of the Moscow Aviation Institute have created a calculation methodology and software that allow selecting the mechanical properties of composite materials for aircraft construction. The methodology is currently being used in work on the CR929 wide-body long-range passenger aircraft, the institute’s press service said.

“The project is being handled by the specialists of Laboratory No. 2 Composite Materials of the Scientific and Research Institute-101 MAI under the leadership of Egor Nazarov. This work becomes especially relevant in conditions of the course taken by the industry on import substitution,” noted in the MAI.

The peculiarity of the development is that the new software allows you to simulate the composition of the composite material, which is close to the real, that is, taking into account technological and manufacturing defects. Most domestic analogues rely on idealised parameters which are not available in practice.

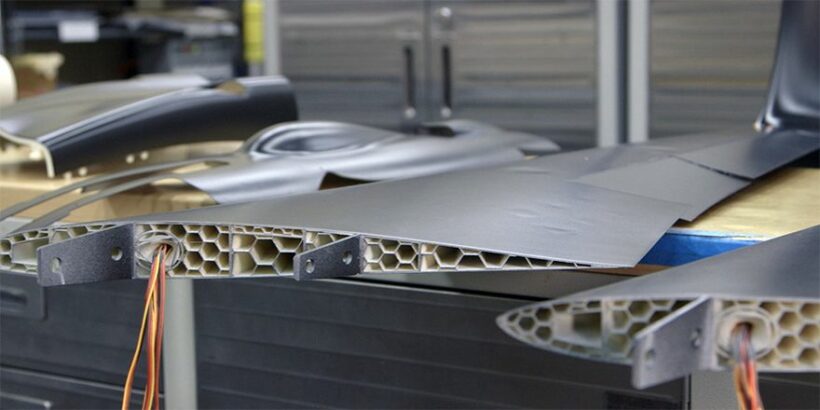

“We consider the composite material as a whole as well as separately fibre, matrix and interface. Inhomogeneities, layering, pores and cracks are added to the model. We investigate whether various inclusions are added to the material, such as nanotubes. All this allows to choose the composite with optimal properties, corresponding to the increased requirements on strength and stiffness,” the expert of the laboratory № 2 Composite materials Konstantin Shramko has told.

He explained that with the help of the developed program the selection of suitable composites for the aircraft will reduce the time and costs for design and testing of the whole airliner as well as its components. Konstantin Shramko believes that the programme may come in handy in the work on other domestic civil aircraft as well.

The work on the project is in line with the strategic project Future Aerospace Markets – 2050 of the MAI development model within the Priority 2030 programme.