The development of digital models based on high-precision mathematical modeling techniques has accelerated the production of new aircraft. Initially, this approach was used to reduce design errors, later on it was applied in flight tests and operations. The United Aircraft Corporation told about modern technologies of aircraft design.

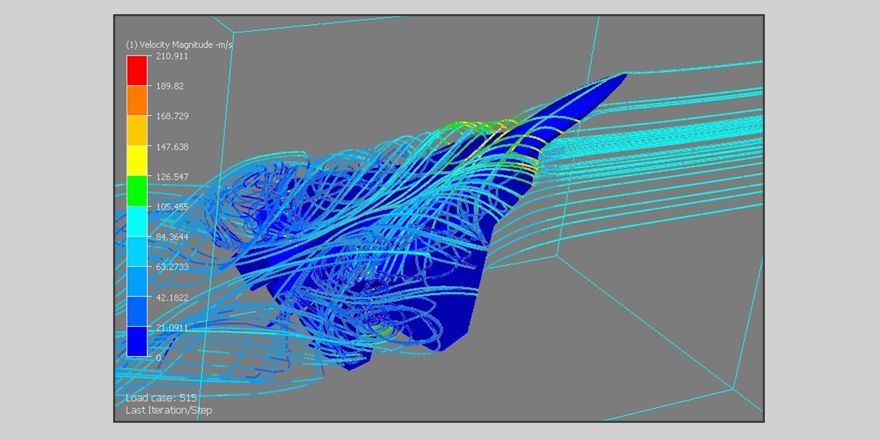

Digital models are used to solve many design problems. For example, due to the requirements of multifunctionality for the fifth generation fighter it was necessary to create an original shape of the airframe. Mathematical models made it possible to test a whole series of different variants. Moreover, if the blowing in wind tunnels would have taken one or two years, on a supercomputer, one version of the glider was calculated from one week to one month.

The method of mathematical modeling allowed for a continuous search and testing of alternatives. In addition, the mathematical model offered another important advantage: it showed a complete picture of the measured parameters at every point of the investigated space or surface. This data proved to be fertile material for engineers to make rational decisions.

Thanks to advances in mathematical modeling it became possible to simulate all aircraft systems simultaneously. Thus, it became possible to apply the concept of digital twins for new aircraft – to create an integrated digital model of the entire aircraft. A digital twin is a set of virtual models of a particular physical process synchronized with a physical object. Such twins track the state of the aircraft in operation and allow predicting their behavior in the future.

The concept of digital twins is multifaceted and allows, for example, predicting how the aircraft will behave in different situations. Or find the causes of failures, study the peculiarities of their occurrence and predict the consequences. It helps a lot to form a harmonized energy balance and to understand the processes of functioning both in standard situations and in critical ones.

Digital twins are needed, first of all, to make it easier for engineers to understand complex physical processes before a full-scale sample appears. But there are also other applications for them, for example – personnel training. After all, the digital twin is able to show the trainee what in different situations should be the sequence of permissible actions in production and operation.

Already, one of the concepts of digital twins, the virtual engineering environment, allows serial plants to improve the assembly and manufacturing processes of serial production. Of course, digital modeling does not replace the work of engineers and production specialists, but it helps to find and make sure that solutions are correct. In this case, experience is formed, which production specialists use when solving new tasks and mastering new products of aviation equipment.

The virtual engineering environment allows to visualize the main stages of production. To be more precise, the process of manufacturing of any part is preceded by the stage of production preparation. To rule out errors and shortcomings, which are sometimes discovered after the part is manufactured, the technological process is refined in a virtual space. As a result, the object studied in the virtual world is launched into batch production, and subsequently the part is manufactured in the shop without any gross deviations.

The aviation industry of Russia together with the leading scientific teams of the country conducts active work on the development and implementation of the concept of digital twins. New subject-oriented and object-oriented mathematical models of aircraft and their infrastructure are being developed and improved.