The most effective and economically expedient areas of application of composites in civil aircraft construction are their use in power structures of the aircraft airframe. Wing, keel, stabiliser, centroplane are characterized by the increased constructive complexity, high level of acting loads and criticality from the point of view of flight safety. The vertical and horizontal feathering caissons of the MC-21 aircraft are manufactured in Obninsk at the production site of Obninsk Research and Production Enterprise Technologiya (ORPE).

The method of manufacturing large-size integral panels of the reinforced type of keel and stabiliser caisson for MC-21 was developed by the specialists of the enterprise in the mid-2010s for the aircraft in the guise of imported composite materials.

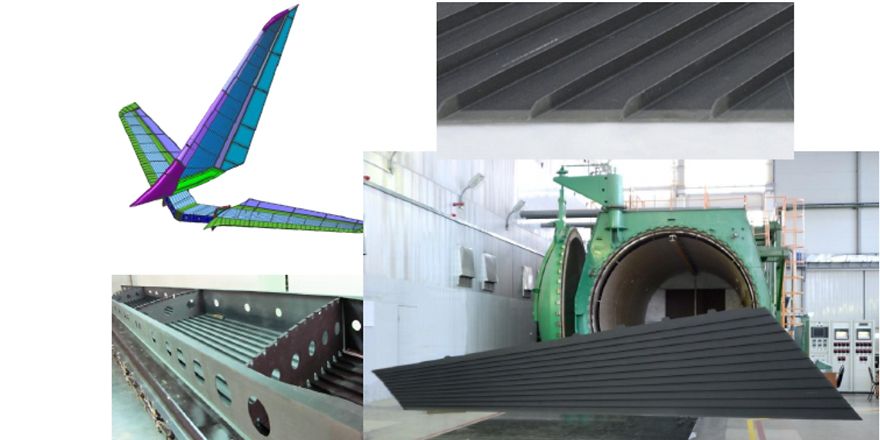

The design of the stabiliser and keel caissons power elements includes spars, ribs, upper and lower panels designed similarly to the power set and wing panels. The keel and stabiliser spars are channel section beams with flanges inside the caisson and moulded struts made of carbon fibre prepreg. The walls of the members have holes for access inside the caisson.

Each caisson panel consists of cladding and stringers moulded together with cladding made of carbon fibre prepreg, thickness of cladding and stringers is variable. The transverse power set of the keel caisson and stabiliser caisson brackets consists of channel-sectioned ribs. At Technologiya ORPE autoclave moulding is used for manufacturing of power structures. Large-size master models and moulding carbon plastic tooling as well as unloaded structures are manufactured by vacuum infusion method. Layout of prepregs and dry carbon fibre is automated using layout robots.

Fabrication of metal parts and general assembly of the composite tailplane is carried out by Aviastar Ulyanovsk. The supplier of composite elements and power structures of the tailplane is Technologiya ORPE. Strength tests of the samples are carried out by the Central Aerohydrodynamic Institute named after Prof. Zhukovsky.

In the summer of 2024, TsAGI conducted tests of the MS-21 stabiliser caisson made of domestic polymer composite materials (PCM) at the request of PJSC Yakovlev. The purpose of the research was to confirm the static strength of the structure at ultimate loads, which is critical for the aircraft’s operational safety.

‘On the isolated stand, previously used for similar studies of units made of imported PCMs, experiments were conducted with the stabiliser caisson not only for general, but also for local strength, in particular, the level of stress state of the linkage units, rudder and stabiliser repositioning mechanism was determined,’ TsAGI said.

In addition, on the caisson were realised loads exceeding the design values by more than 150 per cent. This is more than the load at which the unit made of imported composites collapsed. The deputy head of the static and thermal mechanics department of TsAGI Mikhail Limonin noted that the stabiliser caisson made of Russian PCMs withstood the limit load levels and impact damage simulating real conditions of the aircraft operation, showing high strength and rigidity of the structure.

To prepare a certification opinion on the strength of the MS-21 stabiliser, the results of the experiments were submitted to Yakovlev PJSC. At the moment, TsAGI is conducting strength tests of imported imported glass for passenger cabin portholes. In the near future, studies of the airliner’s cockpit windows and floor elements made in Russia will start.