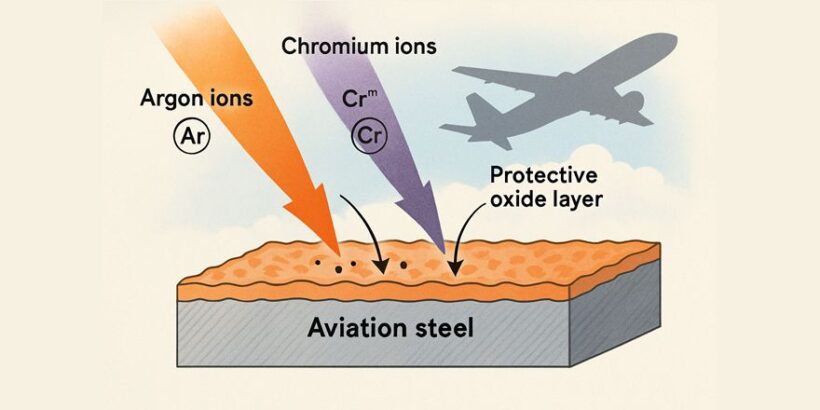

Researchers at the Moscow Institute of Physics and Technology (MIPT) have developed an advanced method for protecting VNS-5 (internationally known as DYc-5) aerospace steel from corrosion using ion implantation. By treating the steel surface with argon and chromium ion beams, the team created a durable protective barrier that enables the alloy to withstand exposure to marine environments and biological agents. This development was reported by TASS, citing MIPT’s Center for Science Communication.

Under the leadership of Senior Research Scientist Viktor Syomin, the team demonstrated the effectiveness of ion bombardment in forming anti-corrosion coatings. This technique provides superior long-term protection compared to conventional chemical passivation, which forms a thin protective layer on the metal surface to inhibit corrosion. The ion implantation method also outperforms existing surface modification technologies in terms of corrosion resistance.

VNS-5 steel (DYc-5) is widely used in the aerospace industry due to its high strength and corrosion resistance. It is commonly employed in the manufacture of structural components for airframes and landing gear in military aircraft, as well as in civil aviation for high-load engine mounting bolts.

Additionally, VNS-5 is utilized in the production of welded assemblies, high-strength fasteners, and other critical load-bearing components that operate under significant mechanical stress and in aggressive environments. Given the high cost of this material, effective protection against degradation is essential.

MIPT specialists compared two approaches to protective coating formation. The first involves immersing components in solutions with a high concentration of ions. The second relies on targeted exposure of the surface to charged particle beams. The latter proved more effective: corrosion current was reduced by a factor of 7.8, while chemical passivation had little impact compared to untreated samples.

The difference in performance is attributed to the structure of the resulting coatings. Ion implantation produces a dense chromium oxide layer several tens of nanometers thick. In contrast, chemical treatment forms a less stable film composed of chromium hydroxide and iron oxides, which does not effectively prevent corrosion.

Ion modification technology paves the way for the development of advanced steels for aerospace and marine applications. This research establishes a foundation for creating materials with enhanced resistance to aggressive environments. The findings have potential applications in protecting critical load-bearing elements of aircraft structures.