Obninsk’s A.G. Romashin Research and Production Enterprise Technologiya has started serial production of glazing for crew cabins and protection of external lighting equipment for the SJ-100 aircraft, Rostec’s press service reported.

“The glazing is produced under the programme of import substitution of foreign components and consists entirely of Russian materials, is equipped with heating for flights in any weather conditions and has passed all ground tests, including bird resistance. Previously, these products were supplied for the Superjet from abroad. The structural optics are installed on the SJ-100 prototype, which is currently undergoing flight tests,” Rostec said.

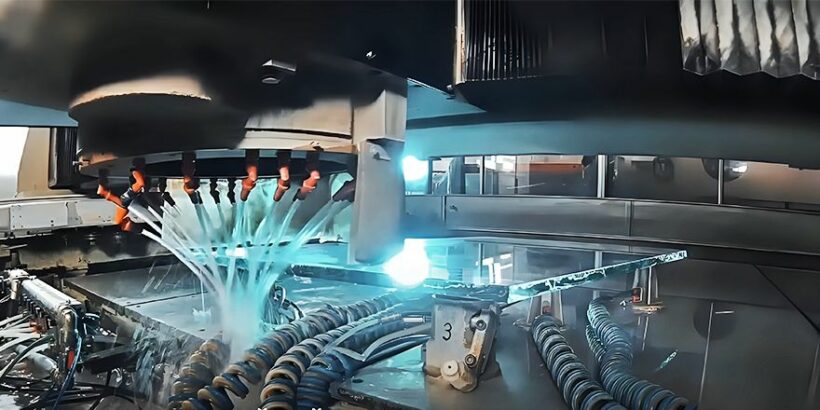

The kit for one aircraft includes six cockpit glazing products that remain functional at temperatures ranging from -62 to +85°C. The windshields and outlets are a seven-plex: four silicate glasses bonded with three layers of polymer film. They can withstand a collision with a bird at a speed of more than 570 km/h without depressurisation. Cabin side windows are triplex made of strong orientated organic glass. The protection of signal lights and other lighting equipment on the wing, fuselage and tailplane is made of organic glass.

By the end of 2023, the PJSC Yakovlev Production Centre in Komsomolsk-on-Amur will receive 20 sets of products for twenty Superjets. “Its output will be increased in the future as Russian aircraft production ramps up,” said Vladimir Artyakov, first deputy director general of Rostec State Corporation.

Three enterprises of the holding in the chemical industry take part in the co-operation on glazing production: specialists of the Research Institute of Technical Glass ensured the application of the electric heating layer, the Research Institute of Polymers ensured the production of organic glass, and employees of Technologiya work on the final products.