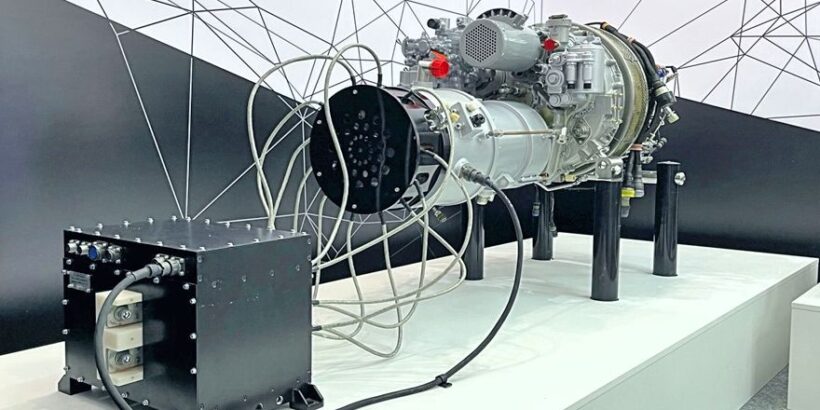

United Engine Corporation’s Klimov facility has developed a 400 kW turbogenerator, weighing 200 kg, based on the VK-650V turboshaft engine. This new domestically produced system is designed for integration into hybrid powerplants for unmanned aerial vehicles (UAVs) operating in Arctic environments. The announcement was made by the United Engine Corporation (UEC) press office.

UEC unveiled the turbogenerator at the “Arctic – Regions” forum, held in Arkhangelsk on July 31 and August 1, 2025. The event focused on key development strategies for Russia’s Arctic zone. According to UEC, this is the first and currently the only Russian-made turbogenerator in its class to offer this combination of power output and weight.

The base VK-650V engine is intended for light helicopters, including the Ansat, Mi-34M1, and Ka-226. In December 2024, the Russian Federal Air Transport Agency (Rosaviatsiya) issued a type certificate for the VK-650V. According to the certificate data sheet, the engine delivers 545 hp for takeoff, 460 hp for maximum continuous operation, and 400 hp in cruise mode.

To increase the specific power of the turbogenerator, engineers modified the engine’s reduction gearbox, adjusting the gear ratio. The high-speed rotor, operating at tens of thousands of revolutions per minute, generates alternating current, which is then converted to direct current at the required voltage by the power electronics module.

“The new turbogenerator incorporates advanced engineering solutions that ensure high reliability. A six-phase generator design allows continued operation even if one phase fails. Its ability to function at low temperatures makes it suitable for harsh climates, including Arctic regions,” said Evgeny Prodanov, Chief Designer at UEC-Klimov.

UEC’s press office added that the reliability of the unit is further enhanced by a liquid cooling system for both the generator and the power electronics. The turbogenerator is rated for a minimum of 4,500 hours for the most heavily loaded hot-section components of the VK-650V engine, 9,000 hours for cold-section parts, and over 10,000 hours for the generator itself.

The hybrid powerplant based on this turbogenerator is intended for use in heavy UAVs and other experimental aircraft requiring low weight, high specific power, and extended autonomous operation far from ground infrastructure. This hybrid system opens up a wide range of applications for Arctic aviation, from rapid cargo delivery and weather monitoring to search-and-rescue missions and maintenance of distributed communications networks.