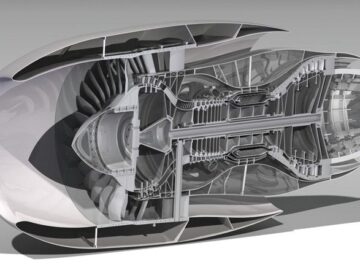

Image © UEC Press Service Gas turbine engine (GTE) blades are a critical component of aircraft power plants. As Soviet engine designer Nikolai Kuznetsov noted, emphasizing their importance, “An engine […]

Read more

Everything you wanted to know about Russian aviation

Image © UEC Press Service Gas turbine engine (GTE) blades are a critical component of aircraft power plants. As Soviet engine designer Nikolai Kuznetsov noted, emphasizing their importance, “An engine […]

Read more

Photo by © UEC Gas turbine engine blades are among the most technologically advanced and challenging components to manufacture. Their creation demands the utmost precision, utilising cutting-edge materials and technologies. […]

Photo by © UEC Over 47,000 passenger aircraft worldwide, and approximately 1,500 in Russia, take to the skies thanks to gas turbine engines. A critical component within their design is […]

Read more

Photo by © UEC press service In 2020, the United Engine Corporation (UEC) together with relevant research institutes completed the development and manufactured the first prototypes of composite fan blades […]

Read more

Photo by © UEC Production of blades for the PD-8 engine from heat-resistant nickel alloys capable of withstanding high thermal loads has started in the innovative foundry complex of the […]

Read more

Photo by © UEC The United Engine Corporation is introducing artificial intelligence to detect defects, including the smallest defects in gas turbine engine blades, according to the press service of […]

Read more

Photo by © Leonid Faerberg / Global Look Press Specialists of the Institute of Theoretical and Applied Mechanics (ITAM) of the Siberian Branch of the Russian Academy of Sciences in […]

Read more

Photo by © UEC Specialists of Rybinsk company ODK-Saturn have invented a new composition of electrolyte, which will repeatedly reduce the time of polishing gas turbine engine blades – up […]

Read more

Turbine blade of the second stage engine “article 30”. Photo by © UEC press service. The durability of modern gas turbine engines depends to a large extent on the reliability […]

Read more