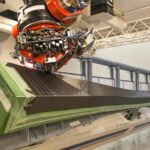

During the production of the composite wing of the MC-21 aircraft at the AeroComposite plant in Ulyanovsk, robotic installations for the dry automated deposition of carbon fibre from the Spanish company MTorres are used. The French company Coriolis Composites supplied the equipment for dry laying of wing spars. The TIAC thermal infusion centres, in which the vacuum infusion process takes place, were developed by another French company, Stevik.

The dry carbon ribbon is heated with a laser, bonded to the previous layer and formed layer by layer to form the future part of the airliner. A spool of ribbon with a length of 3,000 to 3,500 metres provides continuity.

With the imposition of sanctions, the supply of such equipment to Russia has been stopped, but back in 2018 the task was set to completely import substitute French and Spanish robots. It is impossible to obtain such equipment through parallel imports, as the Ulyanovsk plant is the only one in the world’s civil aviation industry that uses dry lay-up and vacuum infusion to make large integral power structures for passenger aircraft.

“The task has been set to replace the French and Spanish robots that we use in the serial production of the MC-21 airliner. They are engaged in automatic dry belt lay-out, which is the base of our serial technology. In connection with known events, the supply of such machines is completely blocked for us, because in the world only we use such machines. Naturally, no parallel import can replace them,” said Anatoly Gaidanskiy, First Deputy Director General of Irkut Corporation, Director General of AeroComposite JSC.

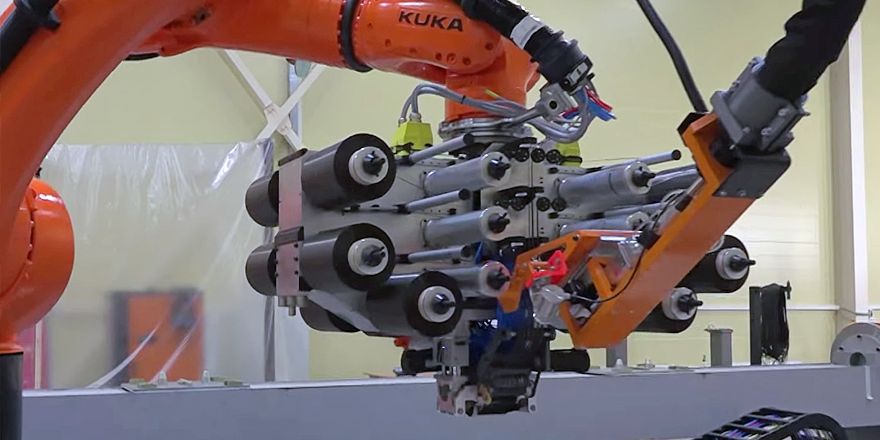

Irkut Corporation in cooperation with the South Russian State Polytechnic University named after N.I. Platov (Novocherkassk) has created the first domestic composite fibre stacker robot. It will replace foreign equipment and will be used in the serial production of the “black” wing of the MC-21 aircraft. All key elements, including software and process control systems, are made in Russia.

“The MC-21 is an important aircraft for our country, on which the sustainability of Russia’s air transport system largely depends. We replaced imported composite materials in its wing in the shortest possible time, having received the approval of the major changes to the aircraft’s standard design from Rosaviation at the end of last year. Now we have also created a Russian stowage robot for the domestic ‘black’ wing that is in no way inferior to its foreign counterparts. The equipment will enable us not to depend on foreign suppliers and will help us to achieve rhythmic production of up to 36 MS-21 aircraft per year,” explained Vladimir Artyakov, First Deputy CEO of Rostec State Corporation.

The prototype of the robot has been put into commercial operation in the Moscow laboratory of the AeroComposite company, which is the centre of UAC’s competence in innovative development and production of parts and units made of polymer composite materials.

“We have fully perfected the domestic technology, achieving high quality, speed and reliability of the system. The next aim is scaling of this solution for serial production of composite wing structures for MC-21 and increase of aircraft production volume”, – noted Anatoly Gaidanskij.

He added that with the implementation of the Russian robotic complex the Russian civil aviation industry becomes import-independent not only in terms of materials but also in terms of the main technological equipment.